Unveiling the Potential of Stone CNC Machines: A Modern Craftsmanship Revolution

Stone CNC Machines: The world of stone fabrication is experiencing a revolutionary shift, thanks to the advent and integration of CNC (Computer Numerical Control) technology. Stone CNC machines have become indispensable tools in the arsenal of modern stoneworkers, blending the age-old artistry of stone crafting with the precision and efficiency of modern technology. This transformative combination not only enhances the capabilities of artisans but also opens up new horizons in the design and production of stone products.

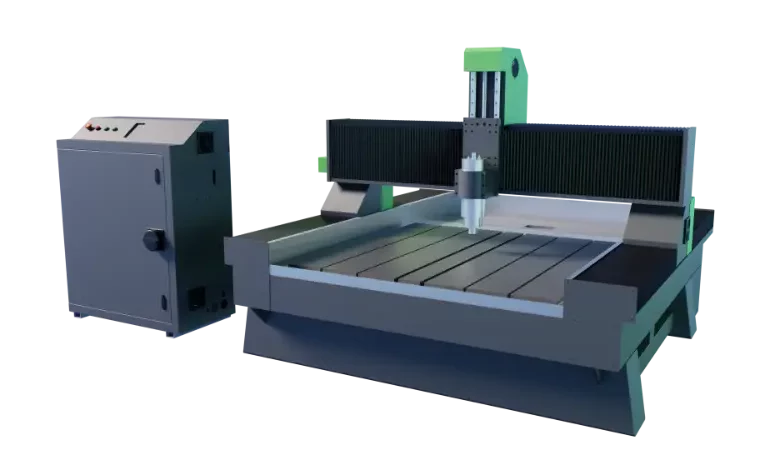

The Essence of Stone CNC Machines

At its core, a Stone CNC machine is a highly sophisticated piece of equipment designed to cut, carve, polish, and engrave stone with unparalleled precision. These machines are guided by computer programs that dictate their movements based on designs inputted by operators. This technology enables the creation of intricate patterns, detailed carvings, and flawless finishes that were once thought impossible or would have required countless hours of manual labor to achieve.

Revolutionizing Traditional Stone Work

The traditional process of shaping and finishing stone is labor-intensive, requiring a high degree of skill and years of experience to master. While the value of handcrafted stone cannot be understated, CNC technology supplements these traditional techniques by providing a level of accuracy and detail that surpasses human capability. The incorporation of CNC machines into stone fabrication marks a significant advancement, allowing for the production of architectural elements, sculptures, countertops, and other stone products with complex designs and tight tolerances.

The Versatility of Stone CNC Machines

One of the most compelling aspects of Stone CNC machines is their versatility. They can work with a wide array of stone types, including marble, granite, quartz, limestone, and more. This adaptability makes them invaluable to a broad spectrum of applications, from interior design and architecture to memorial art and signage. The ability to switch between different types of stone and various cutting and engraving tools allows craftsmen to push the boundaries of creativity and innovation in their projects.

Enhancing Efficiency and Productivity

Efficiency and productivity are among the key benefits offered by Stone CNC machines. These systems significantly reduce the time needed to complete projects, enabling faster turnaround times without sacrificing quality. Automated processes minimize the risk of human error, resulting in consistent and repeatable outcomes. This reliability is crucial in industries where precision is paramount, such as in the fabrication of kitchen and bathroom countertops, where even the slightest miscalculation can be costly.

The Role of Software in Stone CNC Machining

The magic behind the operation of Stone CNC machines lies in the software that controls them. CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software play pivotal roles in transforming conceptual designs into tangible products. Designers can create or import detailed models in CAD software, which are then converted into machine-readable formats by CAM programs. This seamless integration of software and hardware allows for the execution of complex designs with high precision.

Challenges and Considerations

Despite their numerous advantages, Stone CNC machines come with their own set of challenges. The initial investment in CNC technology can be substantial, making it essential for businesses to carefully assess their needs and potential ROI (Return on Investment) before making a purchase. Additionally, the operation of these machines requires specialized knowledge and training. As such, investing in workforce development is crucial for businesses looking to fully leverage the capabilities of CNC technology.

Sustainability and CNC Machining

Sustainability is an increasingly important consideration in all manufacturing processes, including stone fabrication. CNC machines contribute to sustainable practices by reducing waste material through precision cutting and optimizing the use of raw materials. Moreover, the efficiency of CNC machining means less energy consumption per unit of production, aligning with broader environmental goals.

Looking Towards the Future

The future of stone fabrication looks bright with the continuous advancements in CNC technology. As software becomes more intuitive and machines become more capable, the possibilities for creative and innovative stone products are virtually limitless. The ongoing evolution of Stone CNC machines promises to further enhance the precision, efficiency, and creativity of stone fabrication, making it an exciting time for industry professionals and customers alike.

Conclusion

Stone CNC machines represent a pivotal point in the intersection of tradition and technology in the craft of stone fabrication. By offering unmatched precision, versatility, and efficiency, these machines are not just tools but catalysts for innovation and creativity in the field. As the technology continues to evolve, it will undoubtedly continue to transform the landscape of stone craftsmanship, making the once-impossible within reach. In this modern era of stone fabrication, CNC machines stand as a testament to human ingenuity and the endless pursuit of perfection in art and industry.