Introduction:

Printing stickers and labels have become essential to contemporary goods identification, branding, and marketing. Sticker printing company provides High-quality printed materials that are vital for businesses in a variety of sectors to maintain regulatory compliance and increase brand exposure. The need for personalized marketing, growing consumer awareness, and developing printing technology are driving the need for personalized stickers and labels among businesses of all sizes.

Major key Points:

- The Value of Labels and Stickers in Business: Sticker printing businesses provide custom stickers as their primary products to cover packaging requirements build corporate identity and serve promotional objectives. A label printing manufacturer produces specialty labels serving the logistics and food and beverage sectors along with the medicine and cosmetics industries. Essential to product communication industry compliance and brand aesthetics these labels serve multiple purposes. Companies gain access to multiple materials combined with printing methods and finishing options as the industry evolves to satisfy their distinct requirements.

- Branding and Marketing: An effective label or sticker can simultaneously attract customers and build company identity while creating a lasting impact. Businesses utilize personalized stickers across event promotions and giveaways and throughout brands and products for boosting brand identification. For both practical and promotional reasons, stickers and labels are vital business tools. Improving branding and marketing initiatives stands as a primary responsibility for their team. Strategically designed labels and stickers can produce instant customer attraction combined with branding consolidation to create a memorable brand experience. To improve brand identification, businesses use personalized stickers for event handouts, promotional items, and product packaging.

- Product Information and Compliance: In addition to branding, labels include vital product details that support customers in making wise purchases. Ingredients, usage guidelines, safety precautions, barcodes, and expiration dates are frequently among the information they provide. To adhere to health and safety laws, precise labelling is essential in sectors such as food and medicines. Businesses run the danger of facing legal action and losing the trust of customers if they do not properly label their products.

- Packaging Aesthetics: An appealing product label increases outward appearance thus influencing consumer purchase decisions. Companies allocate their resources to create premium labels that catch shoppers’ attention through distinctive colors as well as embossing features and metallic effects or unique shapes. Businesses invest in premium labels featuring unique shapes together with eye-catching colours to create distinctive metal finishes or embossing to gain shelf prominence. Industrial sectors face dramatic competition thus packaging design has become an essential factor.

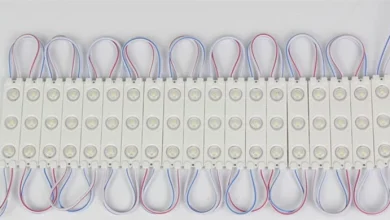

- Custom Paper Labels and Vinyl Stickers: One of the most popular kinds of labels for barcoding, branding goods, and packaging is paper. They are reasonably priced and offer a flat surface for printing of superior quality. However, because they might not survive extreme conditions or wetness, they are best used inside. Vinyl stickers are perfect for exterior applications like window advertising, bumper stickers, and vehicle decals since they are extremely resilient, weatherproof, and water-resistant. They may stick to a variety of surfaces and keep their look over time because of their potent adhesive qualities.

- Polyester and Polypropylene Labels: Different industries select polyester and polypropylene labels for high-durability applications. These materials serve well in industrial laboratory applications since they maintain their integrity against heat exposure and exposure to chemicals and moisture. These materials serve industrial operations including manufacturing facilities automobiles and medical laboratories since they maintain label durability under harsh operating conditions.

- Permanent vs. Detachable Stickers and Specialty Labels: Depending on their requirements, companies can select between everlasting and detached bonds. Detachable stickers are perfect for short-term initiatives and advertising since they are simple to remove without leaving any trace. Conversely, permanent stickers offer durable adherence, guaranteeing that product labels remain in place for the duration of their lifespan. Specialty labels like holographic, embossed, foil-stamped, and translucent labels offer distinctive aesthetics for firms aiming to generate an exceptional experience. These labels provide high-end presentations, cosmetics, and luxury goods with a unique look.

- Digital and Flexographic Printing: One of the most popular methods for producing stickers and labels is digital printing. It provides quick turnaround times together with full-colour, high-quality printing. This technique lowers setup costs by doing away with the requirement for printing plates, making it perfect for small to medium-sized print runs. Digital printing offers flexibility to companies that need to print changeable data, such as customized labels with barcodes or QR codes. Flexographic printing is a common option for large-scale manufacturing. This method is effective for printing in large quantities because it makes use of flexible printing plates and fast-drying inks. Because flexographic printing can withstand high-speed manufacturing, it is frequently utilized for merchandise, food containers, and package labels.

- Offset and Screen Printing: Offset printing is perfect for high-end labels because it offers remarkable colour clarity and precision. Even though mass printing is its main use, it guarantees constant quality in big volumes. Offset printing is frequently used by companies that need upscale package labels or luxury branding materials. When robust colour production and endurance are required, screen printing is utilized. Thick ink layers are applied using this method to produce prints that are durable and striking. This technique is frequently used for industrial labels, outdoor stickers, and promotional decals that require resistance to external variables.

- Customization and Finishing Options: A crucial component of sticker and label printing is customization, which enables companies to produce distinctive designs that complement their corporate identity. Die-cutting, which involves cutting labels and stickers into precise shapes to match a brand’s design, is one of the most often used customization choices. This is very helpful for innovative marketing campaigns, product labels, and brand stickers. Options for lamination and coating are also important for improving the look and robustness of printed materials. While matte finishes offer a refined and high-end sense, glossy finishes add gleam and vitality, bringing out the colours. Foil stamping is an additional high-end customization option that gives stickers and labels shiny elements. These choices assist companies in producing visually striking labels that make an impression on customers.

In the end

Order success across various industries depends on sticker and label printing functions for brand identity and packaging procedures and regulatory standards. Businesses benefit from recent printing technology advances which provide multiple customizable solutions to enhance product offerings and customer interactions. The industry continues to change through focused sustainability practices and intelligent labeling systems as well as tailored marketing strategies. Investing in professional cosmetic labels and stickers not only improves brand recognition but also builds consumer trust by providing clear and accurate product details. Both small businesses and large enterprises should consider investing in professional stickers and label printing because it brings substantial advantages to market control customer belief and brand reputation recognition.